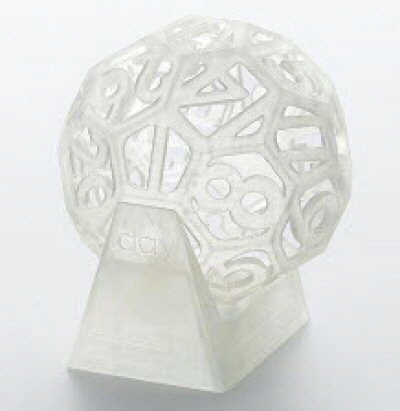

The ARM-10 uses Digital Light Processing (DLP) stereolithography 3D printing that prints layer-upon-layer of resin material which, once exposed to UV light, hardens into a semi-transparent object. This layered projection system of adding and curing converts a digital image created in 3D software into a solid object. By using a suspended build system, resin usage is kept to a minimum, making model production efficient and affordable.

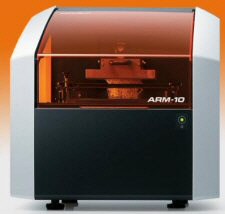

The new Roland monoFab ARM-10 rapid prototyping 3D printer makes creating 3D models as easy as hitting print.

The ARM-10’s layered projection system uses resin material which hardens into a semi-transparent object when exposed to UV light. Complex parts which previously required multi-axis milling, such as hollow or requiring undercuts, can be built quickly and easily.

Feature Summary

- · Digital Light Processing (DLP) layered projection system produces semi-transparent models for concept and form testing

- · Fully enclosed cabinet for safety

- · Easy to use – can be controlled with a single button

- · Build area: 5.11" (130mm) W x 2.75" (70mm) D x 2.75" (70mm) H

- · Material: imageCure™ photopolymer resin

- · Semi-transparent

- · Easy post-processing – removal of supports, polishing and coloring

- · Short post curing time

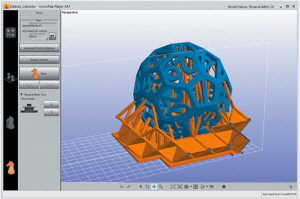

- · Software: monoFab Player AM included

- · Automatic support building

- · Healing and mesh simplification

- · Simulation of resin volume

- · Change scale, duplicate, rotate

- · Preview layer function

- · Roland OnSupport delivers the latest firmware and software to your desktop

Intellecta TECHNOLOGIES

Intellecta TECHNOLOGIES